Products

-

Neon-Helium Purification System

Our neon-helium purification system is a state-of-the-art refinement system designed to produce pure neon and helium. Based on large scale ASU, the device collects raw material gas from the condensing evaporator of an ASU rectification column before undergoing catalytic reaction, adsorption purification, pressurization, heat exchange and rectification processes.

-

Membrane Oxygen Concentrator(Generator)

Membrane Oxygen Concentrator is a kind of VPSA low-energy oxygen source equipment + IoT shared oxygen supply terminal, designed and developed based on plateau conditions. The operating cost of oxygen source has been reduced by more than 50% compared with the current mainstream market. Guarantee lower noise design at the same scale. Cabinet type employs two-stage PSA process, meet 99.5% of oxygen demand.

-

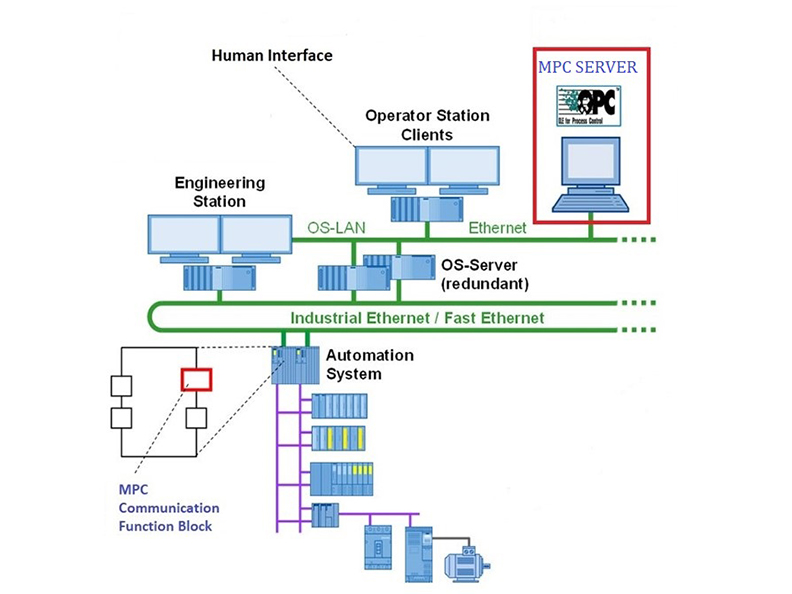

Air separation Unit MPC Automatic Control System

It implements optimal control of the air separation plant, realizes one-key adjustment of the plant load, optimizes the operating parameters of each working case, and achieves overall energy savings and consumption reduction of the plant.

-

Water Electrolysis Hydrogen Production Unit

The water electrolysis hydrogen production unit adopts a unit assembly structure, which mainly consists of an electrolytic cell, a gas-liquid processor (frame), a water pump, a water-alkali tank, a control cabinet, a rectifier cabinet, a rectifier transformer, a flame arrester and other parts.

The working principle of the water electrolysis hydrogen production system is a water electrolytic cell composed of a diaphragm immersed in a pair of electrodes in the electrolyte to prevent gas ingress. When a certain direct current is passed, the water is decomposed, the cathode precipitates hydrogen and the anode precipitates oxygen.

-

Liquid Air Separation Unit

In liquid air separation plants, the product of air separation is liquid oxygen or nitrogen. The principle is as follows: pressurized, pre-cooled air is introduced into the column to participate in rectification, H2O and CO2 are removed via a molecular sieve absorber, cooled to liquefaction temperature in the medium pressure heat exchanger, and then introduced into the column to participate in rectification. The high and low temperature expander and circulating compressor are used to generate cold energy to obtain liquid oxygen and nitrogen products.

Liquid air separation plants typically include an air filter, an air pre-cooling system, a molecular sieve purification system, a high and low temperature expander, a recirculating compressor, a cryogenic freezer, a fractionation column system, and a backup system.