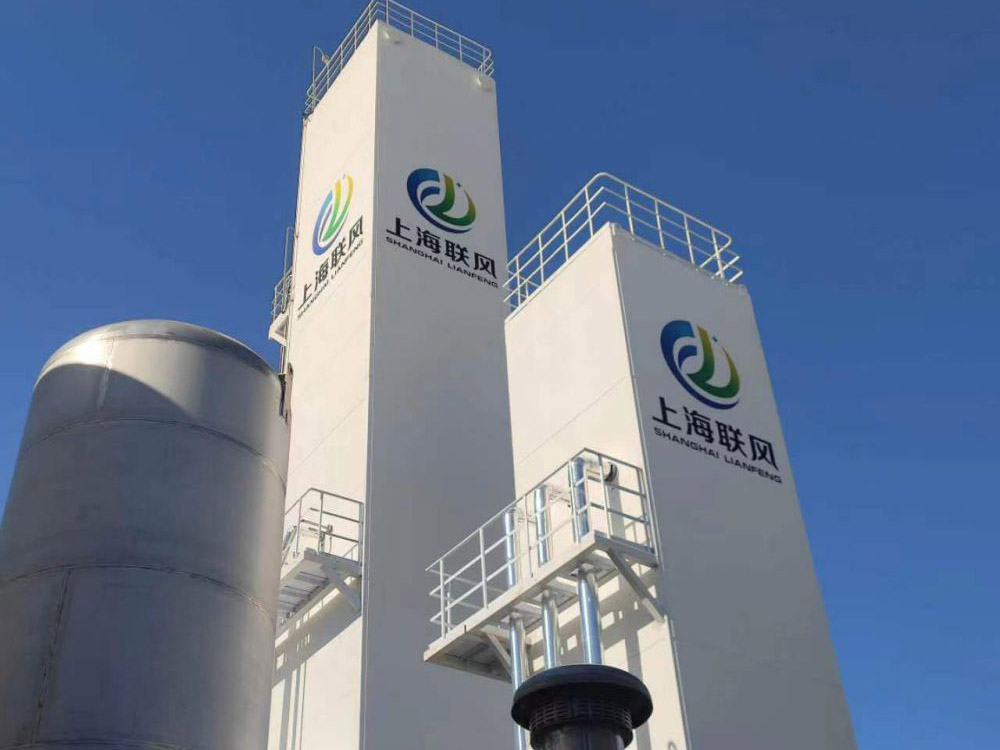

ABOUT US

INTRODUCTION

Shanghai LifenGas Co., Ltd. is a high-tech enterprise that specializes in the production of gas separation and purification equipment with a focus on energy efficiency and environmental protection. Our product portfolio includes:

- Argon recovery units with high recovery rates

- Energy-efficient cryogenic air separation units

- Energy-saving PSA & VPSA nitrogen and oxygen generators

-Small & Medium Scale LNG Liquefaction Unit(or System)

- Helium recovery units

- Carbon dioxide recovery units

- Volatile organic compound (VOC) treatment units

- Waste acid recovery units

- Wastewater treatment units

These products have extensive applications across various industries such as the photovoltaic, steel, chemical, powder metallurgy, semiconductor, and automotive sectors.

-

-Founded in 2018

-

-Patents Approved

-

-+Employees

-

-billion+¥Cumulative Total

products

Innovation

NEWS

Service First

-

LifenGas Awarded JinHong Gas BOG Helium Recovery Project, Advancing Efficient Helium Extraction and Liquefaction

Highlights: 1、LifenGas has secured a major BOG helium recovery project with advanced integrated technology. 2、The system achieves over 95% helium recovery with 99.9999% purity. 3、Innovative cryogenic processes enable efficient extraction from LNG by-product gas. ...

-

LifenGas 2026 Annual Gala Celebrates Growth, Unity, and New Beginnings

Highlights: 1、LifenGas hosted its 2026 Annual Gala to celebrate shared achievements, recognize excellence, and define the direction ahead. 2、Outstanding employees, teams, and five-year contributors were recognized for their impact and dedication. 3、The event energized...

Company History

Milepost