Products

-

Krypton Extraction Equipment

What is Krypton Extraction Equipment?

Rare gases such as krypton and xenon are highly valuable for many applications, but their low concentration in air makes direct extraction a challenge. Our company has developed krypton-xenon purification equipment based on cryogenic distillation principles used in large-scale air separation. The process involves pressurising and transporting liquid oxygen containing trace amounts of krypton-xenon via a cryogenic liquid oxygen pump to a fractionation column for adsorption and rectification. This produces by-product liquid oxygen from the upper-middle section of the column, which can be re-used as required, while a concentrated crude krypton-xenon solution is produced at the bottom of the column.

Our refining system, independently developed by Shanghai LifenGas Co., Ltd., features proprietary technology including pressurised evaporation, methane removal, oxygen removal, krypton-xenon purification, filling and control systems. This krypton-xenon refining system features low energy consumption and high extraction rates, with the core technology leading the Chinese market. -

Neon Helium Purification System

What is Neon Helium Purification System?

The Crude Neon and Helium Purification System collects raw gas from the neon and helium enrichment section of the air separation unit. It removes impurities such as hydrogen, nitrogen, oxygen and water vapour through a series of processes: catalytic hydrogen removal, cryogenic nitrogen adsorption, cryogenic neon-helium fraction and helium adsorption for neon separation. This process produces high purity neon and helium gas. The purified gas products are then rewarmed, stabilised in a buffer tank, compressed using a diaphragm compressor and finally filled into high pressure product cylinders.

-

Oxygen Generator by Pressure Swing Adsorption (PSA)

What is Oxygen Generator by Pressure Swing Adsorption (PSA)?

According to the principle of pressure swing adsorption, the pressure swing adsorption oxygen generator uses the artificially synthesized high quality zeolite molecular sieve as the adsorbent, which is loaded into two adsorption columns, respectively, and adsorbs under pressure and desorbs under depressurized conditions, and the two adsorption columns are in the process of pressurised adsorption and depressurized desorption respectively, and the two adsorbers alternately adsorb and desorb, so as to continuously produce oxygen from the air and supply customers with oxygen of the required pressure and purity.

-

The MPC Automatic Control System of the Air Separation Unit

What is The MPC Automatic Control System of the Air Separation Unit?

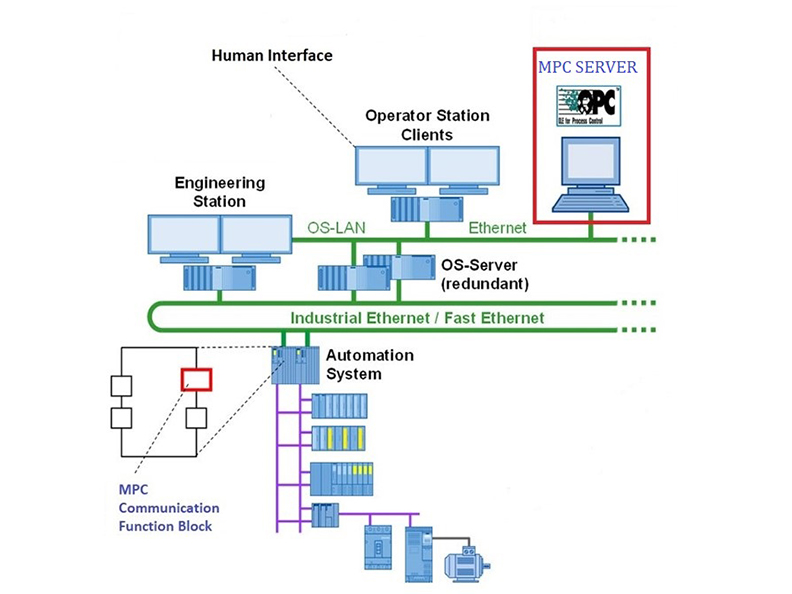

The MPC (Model Predictive Control) automatic control system for air separation units optimizes operations to achieve: one-key adjustment of load alignment, optimization of operating parameters for various working conditions, reduction of energy consumption during device operation, and decrease in operation frequency.

-

Air Seperation Unit(ASU)

Air Seperation Unit(ASU)

An Air Separation Unit (ASU) is a device that uses air as feedstock, compressing and super-cooling it to cryogenic temperatures, before separating out oxygen, nitrogen, argon, or other liquid products from the liquid air through rectification. Depending on the user’s needs, the products of the ASU can either be singular (e.g., nitrogen) or multiple (e.g., nitrogen, oxygen, argon). The system can produce either liquid or gas products to meet different customer requirements.

-

Argon Recovery Unit

What is Argon Recovery Unit?

Shanghai LifenGas Co., Ltd. has developed a highly efficient argon recovery system with proprietary technology. This system includes dust removal, compression, carbon removal, oxygen removal, cryogenic distillation for nitrogen separation, and an auxiliary air separation system. Our argon recovery unit boasts low energy consumption and a high extraction rate, positioning it as a leader in the Chinese market.