Highlights:

1、LifenGas secured a CO₂ capture pilot project in the cement industry.

2、The system uses PSA technology and specialized adsorbents for cost-effective, high-purity capture.

3、The project will validate performance and provide data for future scale-up.

4、The company will keep collaborating with high-emission sectors to advance low-carbon industrialization.

As the world advances toward its “dual carbon” goals, achieving low-carbon transformation in traditional industries has become a global priority. LifenGas has recently been awarded a contract for a Pressure Swing Adsorption (PSA) Carbon Capture pilot project, marking a significant step forward in the company’s capabilities in gas separation and environmental technology. This success adds fresh momentum to the green transformation of industrial sectors.

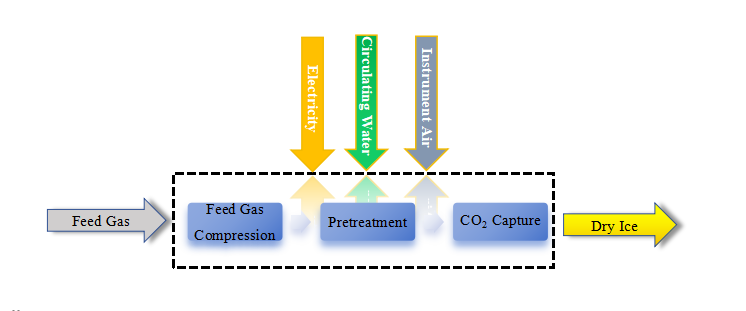

The pilot system will be deployed in industrial settings such as cement plants, offering a practical solution to help high-emission sectors explore and implement carbon reduction strategies.

Utilizing a reliable PSA process combined with temperature swing adsorption and a high-efficiency CO₂-specific adsorbent, the unit efficiently captures and purifies CO₂ from industrial flue gas. It offers notable advantages including low operating costs, operational flexibility, and high product purity. The project will focus on validating CO₂ capture performance under challenging conditions, such as those in cement kiln exhaust, providing customers with essential operational data and experience to support future scaling.

The project manager remarked, “The cement industry faces significant CO₂ emissions and complex capture conditions. This pilot unit allows customers to clearly evaluate the feasibility and economics of the technology. We are committed to leveraging our solid engineering expertise to ensure safe, stable, and efficient operation, delivering reliable data to support their decision-making.”

With years of experience in gas separation and purification, LifenGas has provided solutions including hydrogen generation, air separation, and gas recovery to clients across various sectors. This new project not only reflects the company’s technical strength in carbon neutrality but also demonstrates its active role in supporting industrial decarbonization.

Looking ahead, LifenGas will continue to deepen its expertise in carbon capture and gas utilization, partnering with players in energy, chemicals, steel, cement, and power generation to deploy more green equipment and jointly explore viable pathways toward a cleaner, low-carbon, and sustainable industrial future.

Wei Yongfeng VPSA Technology Director

With years of dedicated expertise in PSA/VPSA technologies, he possesses profound professional knowledge and extensive practical experience. In the pilot CO₂ capture project, he spearheaded the formulation of technical solutions and engineering design, providing crucial technical support that ensured the smooth progress and successful bidding of the project.

Post time: Oct-21-2025